MGA Played A Small But Significant Part Of James Webb Space Telescope Development

Author: Sheron Smith

Posted: Thursday, February 24, 2022 12:00 AM

Categories:

Pressroom | Faculty/Staff | School of Aviation

Eastman, GA

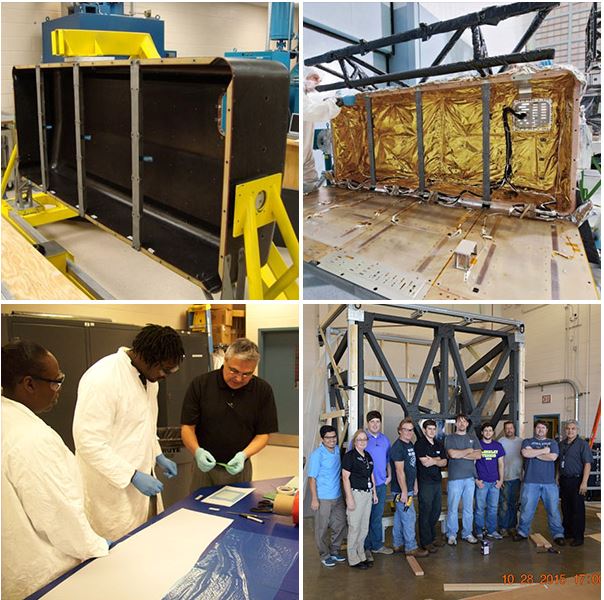

Clockwise: The Integrated Equipment Compartment shell developed by Rick Krontz and his students at MGA's Institute for Applied Aerospace Research; the same shell equipped with radiator panels during James Webb Space Telescope assembly; two photos of Krontz and some of the student interns he worked with over the years at the institute.

In a way, Middle Georgia State University was along for the ride when NASA’s James Webb Space Telescope launched into the cosmos during the early morning hours of Christmas Day 2021.

Years earlier, the University’s Institute for Applied Aerospace Research (IAAR), based on the School of Aviation campus in Eastman, worked on several major to small assemblies, components, parts, and test articles related to the telescope’s development.

Since the Webb spacecraft’s successful launch from atop a European Ariane 5 rocket from South America, NASA has announced it is nearing completion of the first phase of aligning the observatory’s primary mirror using the Near Infrared Camera (NIRCam) instrument. NIRCam will detect light from the earliest stars and galaxies in the process of formation and the population of stars in nearby galaxies, as well as young stars in the Milky Way and Kuiper Belt objects.

As NASA puts it, the James Webb Space Telescope “will find the first galaxies that formed in the early universe and peer through dusty clouds to see stars forming planetary systems.”

Here on Earth, those following the exciting developments closely include Rick Krontz, the now retired director of IAAR. He managed the institute’s telescope-related work and supervised the student interns who helped with the technical work.

“Excitement and pride!” he said when asked how he feels about the latest James Webb news. “We had a program with students of limited technical experience get to help produce high-quality, NASA-certified components that will be a million miles away and that no human hands will ever touch again.”

So how did Middle Georgia State’s (MGA’s) small aerospace research operation end up developing components of the spacecraft known as JWST?

“Originally, the IAAR was an extension of a course called advanced composites and aircraft structures,” said Krontz, who retired from MGA in fall 2016. “This better prepared the students to transition into careers in aircraft structural technology industry. In the early 2000s we had an opportunity to create a state-of the-art advanced composites lab that emulated current aviation industry composite facilities, such as Lockheed, Boeing, Gulf Stream and, later, NASA.

“That provided the capability for students and instructors to work on actual aviation industry-related manufacturing processes and procedures for aerospace structural and advanced composite parts and sub-assemblies,” Krontz continued. “They had to adhere to strict aerospace policies, procedures, and documentation to fulfill NASA requirements. The program enabled instructors and students to experience and maintain up-to-date aerospace policies and processes as opposed to older teaching methods.”

One of the interns who worked with Krontz was James Dix, who had been a student in MGA’s aircraft structural technology program.

“What I specifically did for the telescope project was mostly design and CNC (computer numerical control) machining the molds used for composite fabrication,” said Dix, now 44, who among other things went on teach engineering at Dodge County High School before becoming the current R&D manager at an Eastman company. He’s also back at MGA working on a business degree.

Krontz said MGA’s biggest contribution to the James Webb Space Telescope was the Integrated Science Instrument Module (ISIM) Integrated Equipment Compartment (IEC). ISIM/IEC is located on the backside lowest position behind the telescope’s main mirrors. ISIM is where all the computers that operate and monitor the spacecraft are mounted.

“We fabricated the radiator panels the computers are mounted on,” Krontz said. “The panels absorb the heat generated from the computers and transfer it to the outside into carbon graphite louvers with gold coatings. The louvers direct and reflect the heat in a 20-degree bandwidth out and away from the spacecraft. If the louvers didn’t work as advertised, the project would be at risk. … So far, all of the components we built are working flawlessly.”

MGA’s involvement in developing Webb components lasted from about 2008 to 2016. Over that time, some 30 students served as paid or unpaid interns. “We had a core group of students that became highly skilled technicians filling supervisory roles over less experienced students,” Krontz said, adding that most of the former students are now employed by the aviation industry in some capacity.

NASA recently announced that it expects the James Webb Space Telescope to last longer than its initially predicted 10-year lifespan due to a flawless launch and its efficient maneuvers since then. Which gives Krontz and his former students plenty of time to enjoy their contributions to aerospace research.

“It’s a legacy that will hopefully live on for many years,” Krontz said. “Just to know that MGA and our names are on that spacecraft is almost unbelievable.”

Dix echoed the sentiment.

“I actually watched the launch on Christmas with a big smile on my face, knowing that I had contributed to this immense thing that is going to help us learn so much more about our universe,” he said. “Future generations will benefit from the work that all of us at MGA did during that time.”

Sources include: https://bit.ly/3h1NNbU; https://bit.ly/3h1chlV; https://bit.ly/3JGQsnH; space.com; nasa.gov; Aerospace America.